The restorer said that it would wear in and be fine. It just had some hot spots.

The restorer said that it would wear in and be fine. It just had some hot spots. Fresh Restoration Repairs

Just got a car in after a 4 year restoration. The owner had returned the car days after delivery to have some issues repaired. It was returned a few months later without all of the issues repaired. He then brought it to me to have it made road worthy. Main issues were the clutch sounded like ice cubes in a blender when you pushed in the pedal and the clutch juddered very badly when engaging. Other main issue was steering was so tight, it was very difficult to turn the wheel. Other less severe issues were overheating, not running correctly and vibrations.

First order of business was the clutch. Engine out for this. The throw out bearing had lost it's graphite and was metal on metal. All of the bits and pieces were in the clutch pressure plate and disc. The restorer said that it would wear in and be fine. It just had some hot spots.

The restorer said that it would wear in and be fine. It just had some hot spots.

The rear transmission support had a large washer on the stud with a cotter pin holding it in place. This should be free floating. Once this was removed, I noticed the bushing was missing.  The new bushing is on the left.

The new bushing is on the left.

Clutch was a straight forward replacement. The car had not even had enough miles to remove the nibs from the tires so the flywheel was undamaged. I also ended up taking the rear transmission flange off so that the bolts could be put in facing front to back. They had been installed backwards using washers to compensate for them being to long to go that way.

While the manifold was off, I decided to check the thermostat as part of the overheating issue. This is a 1965 series 1 so should have had a sleeve style thermostat like either of the two on the left. It had a series 2 style, thirs from the left. This was a large contributing factor towards the overheating. Another issue was the owner had been told that the center carb was sticking. They had been rebuild and detailed so not sure why this was delivered with a known problem. Could not find anything sticking but did notice that the throttle plate was not closing all of the way. The carbs had new throttle shafts installed and the hole for the throttle stop had been drilled in the wrong place. As such, it was keeping the throttle open causing the engine to run mainly on the center carb. Add to the problems was the throttle was so far off that the carbs were only opening about 1/3 of their potential.

like either of the two on the left. It had a series 2 style, thirs from the left. This was a large contributing factor towards the overheating. Another issue was the owner had been told that the center carb was sticking. They had been rebuild and detailed so not sure why this was delivered with a known problem. Could not find anything sticking but did notice that the throttle plate was not closing all of the way. The carbs had new throttle shafts installed and the hole for the throttle stop had been drilled in the wrong place. As such, it was keeping the throttle open causing the engine to run mainly on the center carb. Add to the problems was the throttle was so far off that the carbs were only opening about 1/3 of their potential.

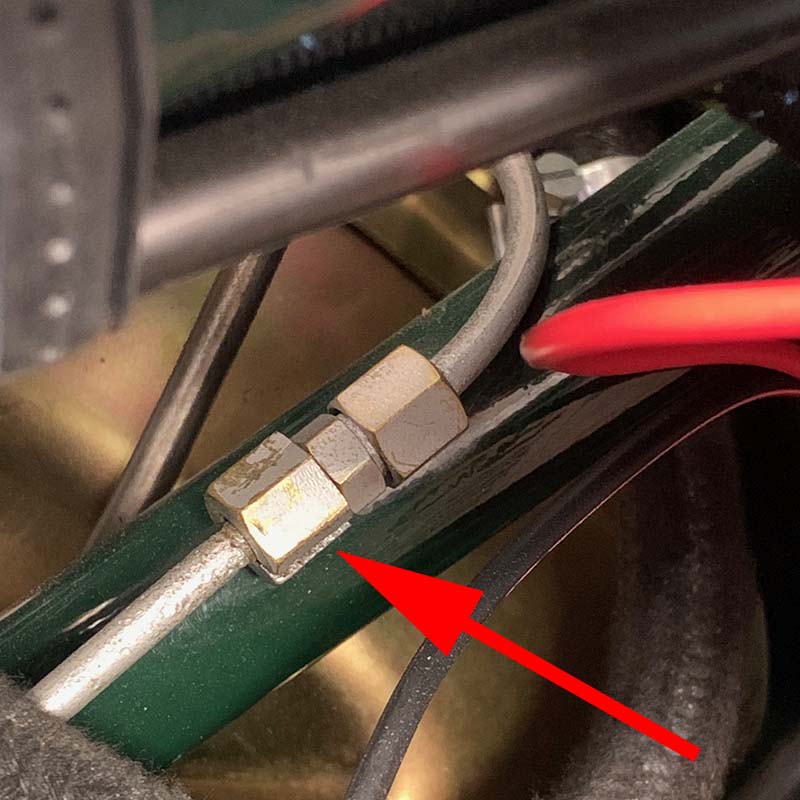

A couple of other items noticed while removing the engine: was a crushed fuel supply line. Probably had to crush it to get a wrench on the tie plate bolt...

was a crushed fuel supply line. Probably had to crush it to get a wrench on the tie plate bolt... And while we are speaking of the tie plate bolt, it is recommended all bolts have a nut on the end. This one was not only missing a nut but the bolt was not even all the way in place.

And while we are speaking of the tie plate bolt, it is recommended all bolts have a nut on the end. This one was not only missing a nut but the bolt was not even all the way in place.

Right sway bar link was slipping out as the large washer was left off. The right side had the washer in place.

Right sway bar link was slipping out as the large washer was left off. The right side had the washer in place.  The front damper also has two bolts secured with a lock plate. The other two use lock washers. There should be at least one tab bent over to secure the bolt.

The front damper also has two bolts secured with a lock plate. The other two use lock washers. There should be at least one tab bent over to secure the bolt.

The lower A-Arm nuts were missing the cotter pins that held them in place. Even worse, the rear lower bushings were missing the washers on the front side that held them in place. The rubber is designed to squish when the nut is tightened. Without the front washers, the bushing just tightens up but does not have anything to stop it on the other end.

The lower A-Arm nuts were missing the cotter pins that held them in place. Even worse, the rear lower bushings were missing the washers on the front side that held them in place. The rubber is designed to squish when the nut is tightened. Without the front washers, the bushing just tightens up but does not have anything to stop it on the other end.

Next step was to address the steering. As I dropped the engine, the steering tie rods were off of the suspension. Steering was very tight even without having to turn the suspension. Turns out that the bushings were not fitted but just installed as they were. I also noticed that the main steeing shaft was in backwards. The upper u-joint that connects to the steering column is larger than the one that connects to the rack. As such, the u-joint was binding onto the subframe and scraping the paint off.

The u-joint that connects to the rack has a allen screw on one end and is integral to the shaft on the other. To repair this, the radiator had to be removed so the shaft could be installed through the subframe properly. Once fitted properly and the bushings sized for the upper steering shaft, the steering was much lighter. The turn signal cancelors had to be repaired and both steering rack tie rods had excessive end play.

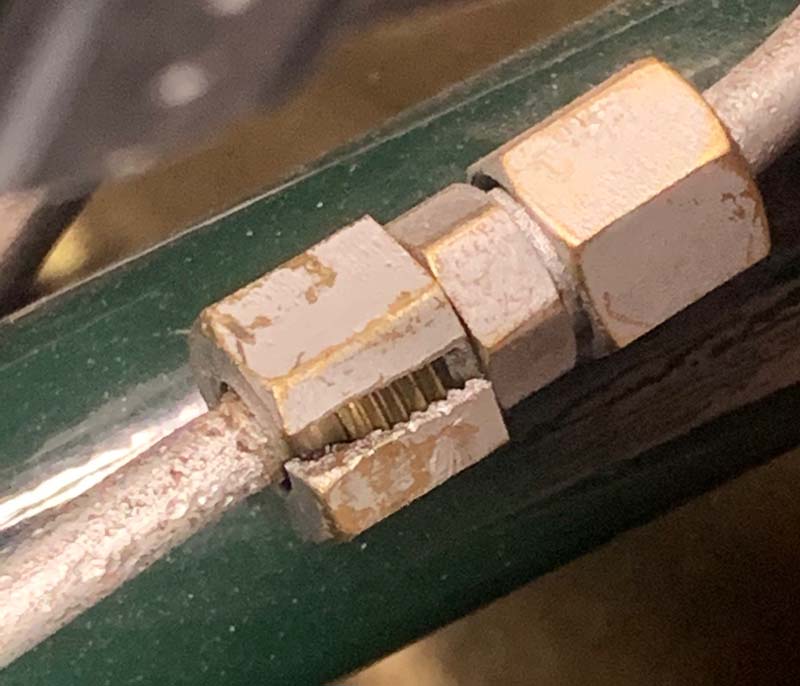

Another item noticed was the use of a brass compression fitting on one of the brake lines. As these are not legal in many states, they are certainly not safe when broken. If that was not bad enough, there was silver paint in the cracked area which means it was installed that way.

Air filters work best when they have all of the air passing through them. There is supposed to be a foam seal on the plenum which was left off. Here it is installed:

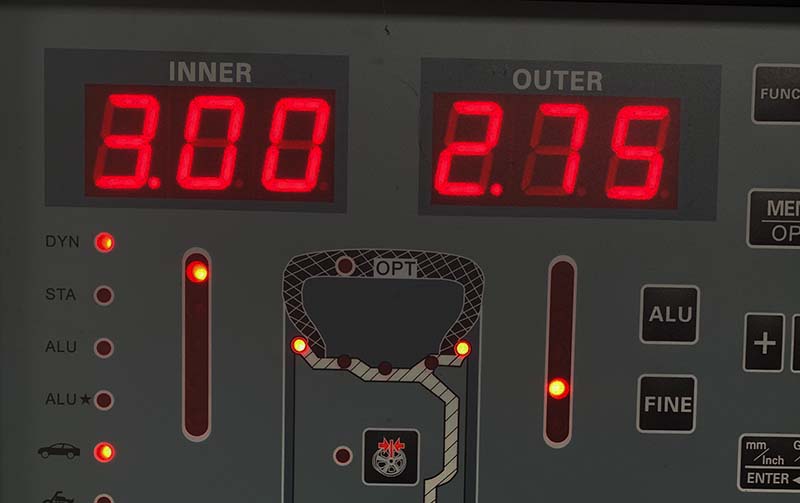

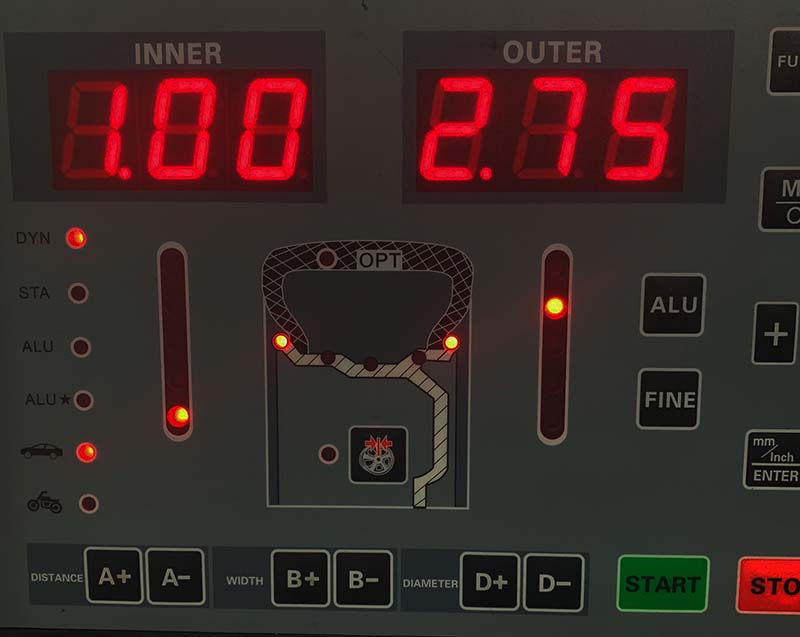

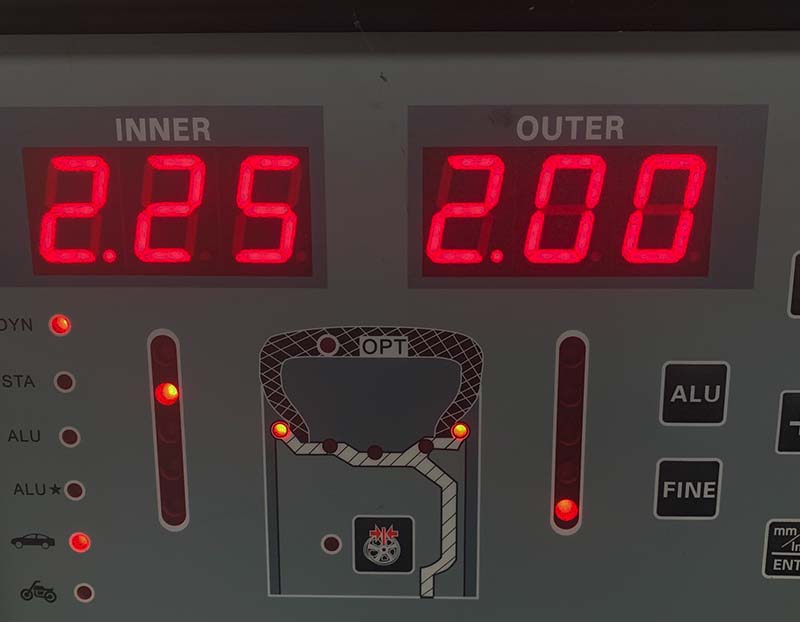

The vibration was addressed next along with a front end alignment. With front camber at 1/2+ on the left and 1- on the right, I knew it had not been set. While the wheels were off, I checked the balance. Less than 1/4 ounce is what you want to shoot for. Here is what the 4 wheels read when put on the balancer. Do realize this was with new tires and rims.

Once all of this was done, car drove out nicely. Now it is off to the upholstery shop to have some issues repaired. When you decide to have your car restored or even worked on, ask for references.